We

are expanding our presence in the Southeast by opening a new Regional Service

Center at 5324 Georgia Highway 85 in Forest Park, Georgia. Set to open on

December 1st, the 21,198-square-foot facility will stock a complete line of

cutting tools, with over 25,000 SKU's for OSG taps, end mills, drills,

indexables, as well as other products including thread gages and holders. We

expect to create at least 10 new warehouse and customer service positions with

this expansion.

OSG's

primary objective is to significantly improve service levels to customers in

the Southeast by reducing delivery times. With the opening of this facility,

our customer support is now available nationwide from the Eastern time zone

through the Pacific, where OSG already operates a facility in Placentia,

California. The Atlanta facility also creates a second fully functional

warehouse operation to service customers in the event of an operations outage

at the main headquarters operation in the Chicago-area.

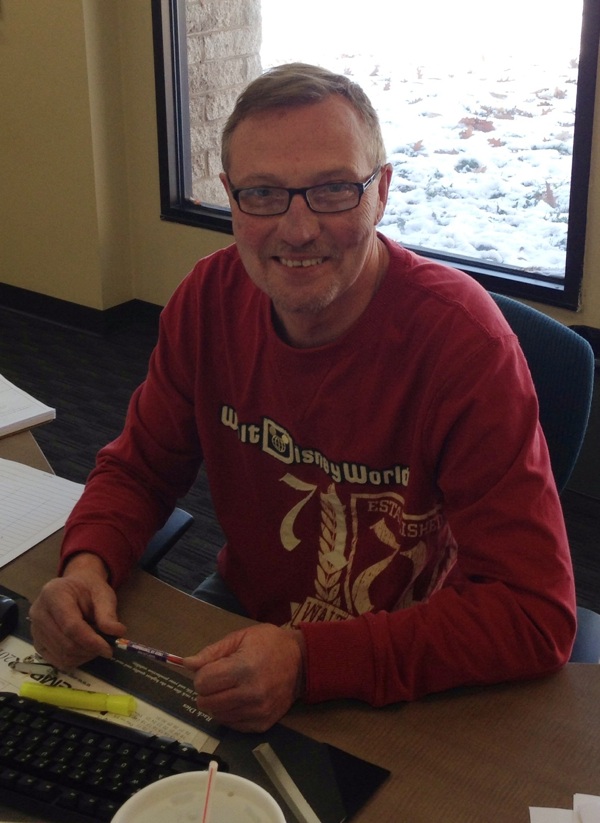

"We

are very excited to expand our operations into the Atlanta area. This new

facility will help improve our order fulfillment times to customers in the

Southeast and give them another reason to look to OSG for their cutting tool

requirements," said OSG President, Mike Grantham.

Contact Us

Contact Us  Product Search

Product Search