New Products

New products

HY-PRO® CARB VGM3-AL

HY-PRO® CARB VGM3-AL

The HY-PRO® CARB VGM3-AL end mill is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials

Features

- Center Cutting

- Variable Index

- Unique Flute Geometry

Benefits

- 3 cutting edges to center; ideal for plunging and ramping.

- Reduces vibration during machining.

- Maintains excellent cutting edge sharpness and tool rigidity.

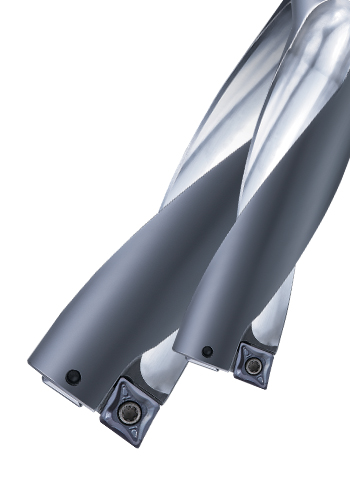

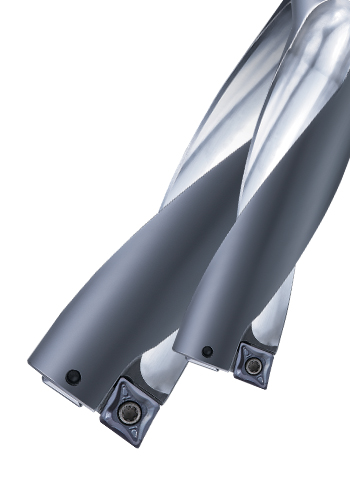

PHOENIX® PDZ-3D

PHOENIX® PDZ-3D

OSG PHOENIX® PDZ indexable flat drill achieves flat-bottom hole machining

Features

- Flat bottom cutting edge configuration

- Enhanced muscle breaker

- High precision finishing on flutes

Benefits

- is compatible with a wide range of applications - drilling, counterboring, inclined surfaces

- Superior chip breaking capability during drilling, counterboring and turning

- Improves rigidity, efficient chip evacuation and reduces cutting force

PHOENIX® PDZ-3D

PHOENIX® PDZ-3D

OSG PHOENIX® PDZ indexable flat drill achieves flat-bottom hole machining

Features

- Flat bottom cutting edge configuration

- Enhanced muscle breaker

- High precision finishing on flutes

Benefits

- is compatible with a wide range of applications - drilling, counterboring, inclined surfaces

- Superior chip breaking capability during drilling, counterboring and turning

- Improves rigidity, efficient chip evacuation and reduces cutting force

Contact Us

Contact Us  Product Search

Product Search